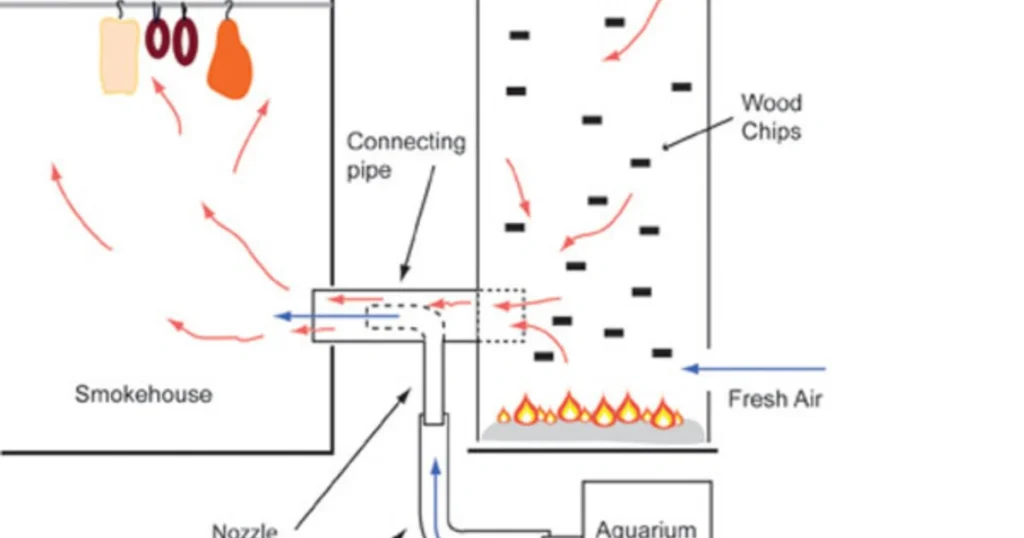

A cold smoking system is designed to flavor and preserve food using smoke without cooking it. The key principle is keeping the smoke cool by separating the fire source from the smoking chamber.

Fire Pit (Smoke Generator)

The process begins in the fire pit.

- Wood burns at a relatively high temperature

- Smoke produced here is warm, around 175°F

- The goal is smoke generation, not direct heat

This chamber is located away from the food to prevent cooking.

Underground Cooling Chamber

The smoke travels through a long underground pipe, often about 6 feet (2 meters).

- As the smoke moves, heat dissipates into the surrounding soil

- The longer the pipe, the more cooling occurs

- By the end of the tunnel, the smoke temperature drops significantly

This step is critical for transforming hot smoke into cool smoke.

Cool Smoke Flow

Once cooled, the smoke reaches approximately 86°F.

- This temperature is low enough to avoid cooking

- Smoke remains dense and flavorful

- Food absorbs smoke slowly and evenly

The arrows in the diagram show how smoke naturally flows upward after cooling.

Elevated Smoking Chamber

The cooled smoke enters the raised smoking chamber where food is hung.

- Meat, fish, cheese, or sausages are suspended

- Smoke circulates evenly around the food

- The target internal chamber temperature stays near 86°F

Because the chamber is elevated, gravity and airflow help maintain steady smoke movement.

Why Cold Smoking Is Effective

- Preserves food texture

- Adds deep smoke flavor without heat damage

- Ideal for cheese, cured meats, and fish

- Allows long smoking times

Cold smoking focuses on patience and control rather than high heat.

Key Takeaway

A cold smoking system works by separating fire, cooling smoke naturally, and gently exposing food to low-temperature smoke. The underground cooling channel is the most important element, ensuring flavor without cooking.

Guided Pamukkale tours I had a very positive experience with Travelshopbooking. The tour was well planned, transportation was comfortable, and accommodations were clean. The guide explained everything clearly and was always available for questions. I would definitely consider booking with them again. https://linkbio.co/7123012UvYhTo

wikipedia reference https://web-breadwallet.com/

Если вы планируете отдых на озере Шира, стоит заранее задуматься о вариантах размещения. Туристические базы на Шира предлагают разные варианты — от простых домиков до более комфортных комплексов с бассейном. Скажем, база отдыха Шира Жемчужный славится уютными шира домиками и хорошими условиями для семейного отдыха. Для тех, кто хочет найти жилье рядом с природой и примечательными местами, подходящим ориентиром могут стать базы отдыха Шира с бассейном или базы 3 звезды Шира, а также особенный сад камней Шира, который стоит обязательно посетить. Подробную информацию можно посмотреть на шира отдых .

Если на первом месте цена и хорошее расположение, то база отдыха Жемчужный Шира послужит отличным выбором — здесь как правило можно найти предложения шира жемчужный снять домик по адекватной цене. Поклонники каякинга и водных занятий точно оценят катекс Шира и бегущую по волнам Ширу как составляющую активного озеро Шира отдых. Итак, если планируете шира отдых, рекомендуется тщательно найти базу отдыха на Шира и заблаговременно бронировать жильё, чтобы насладиться комфортное и приятное время.

why not look here https://toast-wallet.net/

Pamukkale necropolis visit I enjoyed the guide’s energy and knowledge. https://travelshopbookingcom.univer.se/

https://t.me/s/It_EZcash

https://t.me/s/it_ezCaSh

https://t.me/s/It_Ezcash

link

create android apk from website

browse around this web-site https://toast-wallet.net

check it out toast wallet recovery

navigate to these guys toast wallet download

этот сайт

сундук для хранения New World, сундуки New World

read this article

android app from website

нажмите, чтобы подробнее

new world билды

click this link here now toast wallet download

my review here

no-code app builder

посетить веб-сайт

топ билды для нв

click to read https://lumi-wallet.io

Система iQOS представляет собой технологичной системой для нагревания табака.

В отличие от обычных методов, устройство использует нагрев.

Такой подход дает возможность избежать процесса сгорания.

Система отличается компактным дизайном.

DELIA в наличии

Простота эксплуатации делает устройство популярным выбором для многих пользователей.

Также iQOS предоставляет стабильную работу.

Выбор вариантов помогает найти подходящий формат.

В целом, система iQOS стала частью современной культуры среди взрослых пользователей.

Read More Here jax wallet

Если вы собираетесь поездку в Берлин, следует обратить внимание на знаковые места, такие как берлинская стена и замки Берлина — например, берлинский дворец и другие замки в пригородах Берлина, которые замечательно подойдут для суточных экскурсий. Для тех, кто следит за историей, поездка в Потсдам из Берлина — это отличный вариант, и кстати, добраться туда можно чрезвычайно удобно: берлин-потсдам как добраться — во всех подробностях расписано тут лодзь берлин поезд .

Вдобавок, для путешественников из Польши и Украины значима информация о промежутках и способах путешествия: скажем, познань-берлин расстояние, лодзь-берлин поезд или днепр-берлин поезд, а также ужгород-берлин поезд. Если прибываете в аэропорт Берлин-Бранденбург, рекомендуется заранее определить, как добраться из аэропорта Берлина до автовокзала Берлина или других секторов города — это убережет много периода и сил на месте.

Если планируете поездку по Италии, обязательно учтите, что расстояние между Римом и Флоренцией не такое большое, и следование на поезде требует около 1,5 часа. В Риме важно посетить Площадь Венеции, Палацин и гору Авентина, а во Флоренции – знаменитую Сикстинскую капеллу и различные достопримечательности. Для осмотра по Венеции на 1 день хорошо подойдет маршрут для ходьбы маршрут, который даст возможность увидеть основные места, вместе с гондолу на каналах и Пьяцца Венеция. Полезный пример маршрута и карта есть здесь доломитов .

Если желаете добавить природу в маршрут, настойчиво рекомендую исследовать Доломитовые Альпы: маршруты на машине и пешком очаровывают своей красотой. Также следует знать, как переместиться из Милана в аэропорт Бергамо, а дорога из Генуи до Портофино и из Рима до Амальфи забирает времени, но впечатления стоят того. Не обойдите вниманием про Перуджу, если подыскиваете менее туристические, но очень колоритные города Италии.

go to the website

https://russian-traditional-clothes.com

Мы изготавливаем дипломы любых профессий по доступным ценам. Цена может зависеть от выбранной специальности, года выпуска и ВУЗа: 999plots.com/author/cfnsam19121388